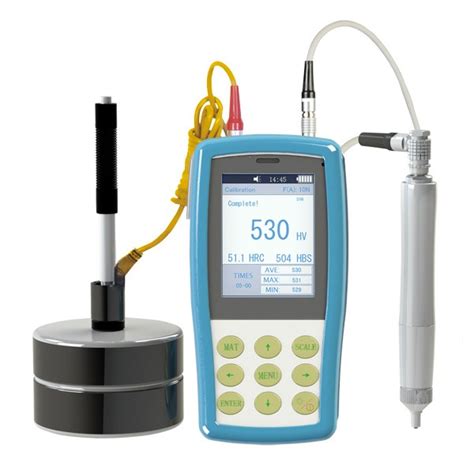

uci method for hardness testing|uci hardness tester : solutions For decades already, the UCI method (Ultrasonic Contact Impedance, as defined in standards ASTM A1038 and DIN 50159), has achieved a good reputation as simple, reliable and quick .

web22 de jan. de 2024 · São Paulo pode salvar o Corinthians do primeiro vexame em 2024. Na Copinha 2024, o Novorizontino garantiu a classificação para o mata-mata na 2ª posição do Grupo 6. Entrando na fase eliminatória, o time do interior paulista passou por gigantes do futebol nacional como Botafogo, Tiradentes-PI, Athletico Paranaense e São Paulo.

{plog:ftitle_list}

Easily share content while you browse the internet. zShare for Chrome, Firefox, Safari and Opera lets you curate and share content from within your web browser without having to leave the page you're on.

The UCI method (Ultrasonic Contact Impedance or modified Vickers procedure) – first put to use in 1965 under the name “SonoDur” - electronically evaluates each Vickers hardness test indentation in a fraction of a second and displays . 1.1 This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method). 1.2 The values stated in .The UCI method. The UCI principle determines hardness by measuring the frequency of an oscillating rod. The rod consists of a metal shaft with vibrating element and a pyramid-shaped .UCI and Rebound hardness testing with just one instrument! The brand-new Krautkramer MIC 20 combines the two most successfully applied portable hardness testing principles in one instrument. Whether you want to use the .

The UCI (Ultrasonic Contact Impedance) method is a portable and versatile modern technique for testing hardness. It operates on the premise that the frequency of an .

For decades already, the UCI method (Ultrasonic Contact Impedance, as defined in standards ASTM A1038 and DIN 50159), has achieved a good reputation as simple, reliable and quick . The ASTM A1038 test method covers the determination of comparative hardness values using the Ultrasonic Contact Impedance Method (UCI Method). The values reported .

With the invention of the UCI method (Ultrasonic Contact Impedance) in 1961, a hardness testing method was described for the first time that determines the Vickers hardness under load and thus records the full .ASTM A1038 test method determines comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method) on metallic samples. The UCI hardness test can be . They also can perform hardness tests on larger, harder metals, as well. Another reason for the rise in popularity is due to the fact that the UCI method is categorized as nondestructive. The UCI method is intended not to replace traditional Vickers testing, but rather to complement it with a quick, field portable test method.2 UCI hardness test method 2.1 The UCI measuring principle As the name ‘ultrasonic contact impedance’ suggests, the principle is based on the use of ultrasound excitation to determine the hardness of the test piece. A resonating rod is set into a longitudinal oscillation by multiple piezo elements, mounted to the upper end of the rod.

ultrasonic hardness tester

Hardness testing is absolutely critical in many industries and phases of manufacturing. Detecting defects during this process can save thousands of dollars and a lot of headaches later due to product or structural .UCI method for the hardness testing: Ultrasonic Hardness Tester's Motorized Probe: 0.3/0.5/0.8/1kgf. The UCI hardness measuring method complies to ASTM A1038. The ultrasonic contact impedance (UCI) probe is purposed to be used for hardness measuring testing areas with minimal thickness (starting from 1 mm). It is specifically designed for .UCI method and dynamic rebound hardness testing. The decision as to which method is used mainly de-pends on the test task. Fig. 1: Hardness testing with a UCI instrument on the tooth flanks of a pinion shaft. Fig. 2: Hardness testing with a rebound tester on the drive wheel of a large hydraulic digger.

The ASTM A1038 test method employs the Ultrasonic Contact Impedance Method (UCI Method) to determine comparative hardness values in metallic samples. This technique holds significant importance in various applications, including assessing the quality and hardness of surfaces that are difficult to access.The method is relatively straightforward, but would be subject to similar limitations to the rebound testing method. The three main principles behind many other types of portable hardness testers are: 1. Ultrasonic Contact Impedance (UCI) - e.g. Krautkrämer Microdur models 2. Rebound methods - e.g. Equotip or Krautkrämer Dyna models 3.Hardness testing using the MIC 20 in combination with the test support MIC 227 and a UCI probe in the heat-affected zone (HAZ) of a weld. Fig. 2: Hardness testing with a rebound hardness tester (DynaMIC) on the drive wheel of a large hydraulic excavator. Fig. 3: Hardness testing using the DynaPOCKET on the chain of an open-pit mining excavator .Fig. 2: Displacement of frequency with increasing test load during the UCI hardness test BAQ GmbH Hermann‐Schlichting‐Straße 14 D‐38110 Braunschweig Tel.: +49 (0)5307 95102‐0 Mail: [email protected] web: www.baq.de 4

The SONODUR 3 provides two different technology standards for hardness testing: The UCI method (Ultrasonic Contact Impedance) and the Leeb method. The user-friendly SONODUR 3 is designed for rough everyday use. The mobile high-tech all-rounder is used for quality control at incoming goods or during the production process. Another field of .

Test methods UCI method: hardness testing with an indenter according to Vickers, evaluation of the test indentation under load. Rebound method according to the ASTM standard specification A956: dynamic test method with a ratio of rebound (Rp) and impact (Ip) speed with hardness output in Leeb HL = 1000 Rp/Ip UCI probes

UCI method for the hardness testing. The UCI hardness measuring method complies to ASTM A1038. The ultrasonic contact impedance (UCI) probe is purposed to be used for hardness measuring in the case of the testing area minimal thickness (from 1 mm), objects of complex surface shape, and for measuring surface hardened layers hardness. .The UCI (Ultrasonic Contact Impedance) method uses the same pyramid-shaped diamond as a conventional Vickers hardness tester. Unlike Vickers testing, no optical evaluation of the indentation is required, enabling fast and portable measurements. The UCI method excites a rod into an ultrasonic oscillation.

UNIVERSAL TENSILE TESTER warehouse

The UCI (Ultrasonic Contact Impedance) method can be used to measure the hardness on a wide field of applications. In this Video we explain the UCI Technolog. This shows the basic technique for making a UCI method hardness measurement with the Waygate Technologies Krautkramer MIC-10 instrument and MIC-205 UCI probe.There are two different physical methods which are particularly recognized in the practical field: the static Ultrasonic Contact Impedance (UCI) method and dynamic rebound hardness testing (Leeb). The decision as to which method .

Bursting Strength Tester warehouse

UCI Method for Hardness Testing: The UCI hardness measuring method complies to ASTM A1038. The ultrasonic contact impedance (UCI) probe is purposed to be used for hardness measuring testing areas with minimal thickness (starting from 1 mm). It is specifically designed for objects of complex surface shape, and for measuring surface hardened .PCE-5000 is a portable hardness tester that uses the ASTM A1038 ultrasonic contact impedance (UCI) method to measure the hardness of metals and alloys with a minimum thickness of 2 mm / .08 in. Ultrasonic hardness testing is considered nondestructive, as it creates a microscopic indentation only visible when using a high-powered microscope. The UCI (Ultrasonic Contact Impedance) method is a portable and versatile modern technique for testing hardness. It operates on the premise that the frequency of an oscillating rod changes when it penetrates a sample. The UCI technique is ideal for fine-grained materials, narrow components, and components with hardened surfaces. Understanding How .

Advanced methods consist of the Leeb rebound hardness test and the Ultrasonic Contact Impedance (UCI) method. Hardness testing standards have been set by various organisations such as The American Society for Testing and Materials (ASTM) and The International Organisation for Standardisation (ISO), prescribing specific varieties of a hardness .The hardness measurements are made by using the dynamic rebound testing method according to Leeb, the static Portable Rockwell hardness test and the Ultrasonic Contact Impedance (UCI) method. The rugged Swiss-made metal NDT hardness testers are designed for portable hardness testing in the lab, in the workshop, at production facilities or on site.Flexible UCI hardness tester for fine-grained material with any shape and heat-treated surfaces. The patented adjustable test load enables a wide range of applications. . The 3 Most Reliable Portable Hardness Testing Methods. Learn more. Application Note Investigating the Strength and Condition of Rocky Coastal Platforms and Maritime Concrete.In order to avoid the creation of a new method involving a new hardness scale, the UCI method converts into common hardness values, for example, HV, HRC, etc. 4.2 The UCI hardness test is a superficial determination, only measuring the hardness condition of the surface contacted.

The SonoDur 3 works with a suite of 18 different probes with test forces ranging from 1N-98N, making it the most universal UCI hardness testing solution available. The new system makes the transition seamless with an intuitive interface and touchscreen as well as with the latest available technologies in OS, statistical data management, and . 1.1 This test method covers the determination of comparative hardness values by applying the Ultrasonic Contact Impedance Method (UCI Method). 1.2 The values stated in SI units are to be regarded as standard. No other units .

ultrasonic contact impedance hardness tester

However, UCI as well as the rebound method can be influenced by the mass of the part to be tested. Generally because of the relatively small indentation created by the Portable Rockwell or UCI methods, they are best suited for testing fine-grained materials having a variety of shapes and sizes. ReboundThe UCI method is recommended for testing fine grained material having any shape and size. It is especially used where material properties are to be processed with narrow . Applications for UCI and rebound hardness testing. Application UCI testing Rebound testing Solid parts +++ Coarse grain materials-++ Steel and aluminium cast alloys o++ .

uci method pdf

Resultado da 18 de dez. de 2023 · A solução do Casino Heist Escape Room - Uma análise detalhada da jogabilidade. Você já sonhou em participar de um .

uci method for hardness testing|uci hardness tester